Product development: Microscope cover for Würth Industrie Service

Innovative solution finding with the use of additive manufacturing

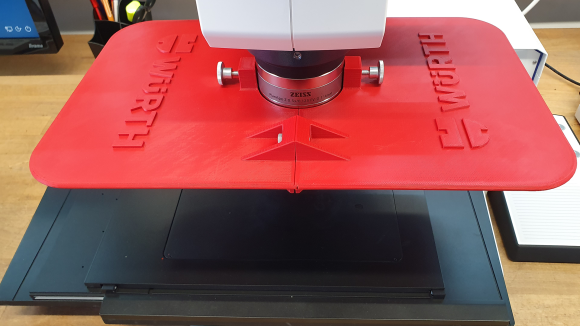

The advantages of 3D printing are also being used at Würth Industrie Service. We manufactured a cover for a microscope in our laboratory, in order to reduce the effect of ambient light.

Initial situation: Finding a solution to reduce reflections on the microscope

During the commissioning of a newly acquired microscope in the test laboratory of Würth Industrie Service, it was evident that the recorded images showed mirroring and reflections whereby the images could not be used for the desired test.

Temporarily, the ambient light was provisionally shielded – however, a sustainably effective solution was being sought for the permanent application.

Additive manufacturing enables quick identification of solutions

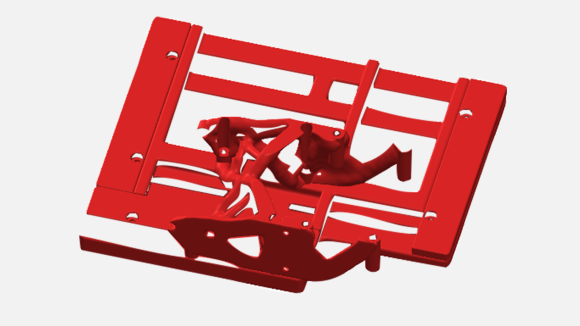

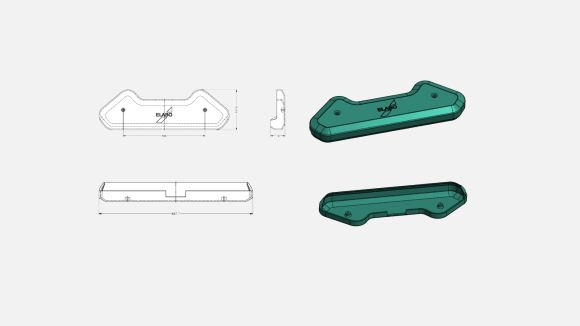

After researches revealed that there was no standardised solution for the light reflections for this microscope, the CPS®WAM colleagues looked at the use case and designed a customised 3D model of a microscope cover that shields the ambient light as well as glossy surfaces.

With the use of additive manufacturing on the company’s printer, the cover could be printed and tested immediately. The first print of the cover right away fulfilled all requirements: optimal serviceability, high-quality, durable material and an attractive design.

Factors of success

The tool costs would have been higher and the production times would have been longer if the same was executed with conventional manufacturing procedures. Since the component is required only once and a fast solution was called for, additive manufacturing turned out to be the ideal technology.

Würth Industrie Service is the optimal partner for such types of product requirements as our CPS®WAM experts guide you from product development of the idea, through the design up to its manufacturing with their know-how.

Additional information

Contact

We are here for you!

Please contact us by telephone +49 7931 91-3288 or

via E-Mail under additivemanufacturing@wuerth-industrie.com.

Websites can save or retrieve information in your browser in the form of Cookies. This may be anonymous statistical data, information about you, your settings or devices used, in order to enable a personalised web experience or so that the website works in the way you are expecting it to.

We respect your right to protection of your data. You can therefore decide not to accept certain types of Cookies. For an overview and the settings for the Cookies which we use, please see here. You can change these settings at any time, by invoking our Data protection declaration.

By saving, you confirm that you have understood the settings specified for Cookies and that you agree with them.

The Würth Industrie Service GmbH & Co. KG collects and processes the personal data provided in the form in order to process the requested request for you. Please note the mandatory fields in the forms. The legal basis for this processing, the absolutely necessary data, is Art. 6 para. 1 lit. b DSGVO, implementation of a pre-contractual measure. The processing of data voluntarily provided by you is carried out on the basis of Art. 6 para. 1 lit. f DSGVO. Thereafter, processing is permissible which is necessary to safeguard our legitimate interests. Our legitimate interest is to have contact with you, our customers, to improve our consulting quality and to be able to contact you more easily in case of possible queries. The data collected will only be stored by us for as long as is necessary to process your enquiry and to contact you. They are then deleted.

Supplementary data protection information, in particular regarding your rights to information, correction, deletion, restriction of processing, objection and complaint, can be found in our data protection declaration.